Paris, Friday 24th June 2022 – ADIONICS achieved a major advance in the field of Direct Lithium Extraction by producing a purified lithium chloride concentrate from natural brines provided by ERAMET last month in ADIONICS’s pre-industrial Clean Lithium 250 plant in France. The technology developed by ADIONICS is based on the implementation of a patented liquid-liquid extraction process from brines and a highly selective extraction formula (the Flionex®) for lithium salts.

The decarbonization of economies is becoming a major challenge that needs to be tackled in the upcoming years. The percentage of world electric vehicles is estimated to represent between 30 and 50% of the total number of vehicles in 2050. With the skyrocketing demand in Lithium, a supply shortage is forecasted for the upcoming years if Lithium production is not accelerated to balance the growing demand. ADIONICS technology can make a huge contribution to this acceleration.

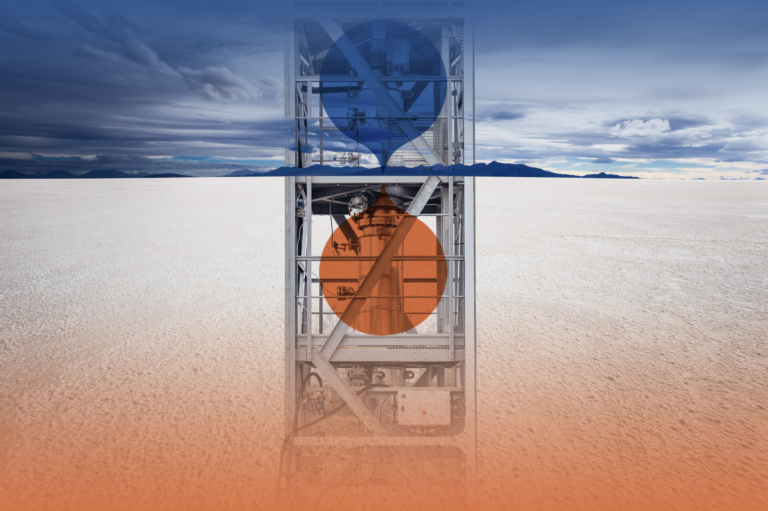

ADIONICS successfully completed a continuous and stable operation of Lithium extraction from brines using the patented technology at a desired pre-industrial scale. ADIONICS Clean Lithium 250 pre-industrial plant has a maximum production capacity of 250 tons of LiCl (Lithium Chloride) per year. The successful results lead to the generation of a high concentration and high-quality product from natural brines provided by ERAMET, a global mining and metallurgical group, from its Argentinian site of Centenario. These groundbreaking results demonstrate once again the process robustness and repeatability.

From this pre-industrial scale is possible now to go with no risk to an industrial plant producing between 10 to 40 KTons/year of Li with significant lower Capex and Opex.

Mr. Gabriel Toffani ADIONICS CEO stated that « ADIONICS is very pleased to have successfully completed the operation on our Clean Lithium 250 pre-industrial plant. We want to thank the ERAMET team for their support to ADIONICS successful technology to reach full commercialization in the coming months».

The mathematical model developed by ADIONICS allows to predict -for full spectrum brine type the performance of Lithium extraction, scrubbing and regeneration. This step allows to proceed with preliminary process optimization of the whole value chain up to high purity Lithium Chloride, Lithium Carbonate, Lithium Hydroxide.

This Direct Lithium Extraction (DLE) is a great lever to reduce the environmental footprint along energy, water, production time. ADIONICS’ technology makes it possible to achieve lithium extraction yields from 85 to 99% when the conventional processes based on natural evaporation ranges between 35 and 50% along with a high Lithium Chloride brine purity from 90% to 99%, therefore obtaining Premium Battery Grade in Lithium Hydroxide or Carbonate. This innovative process will create new market opportunities for lithium extraction and battery manufacturing economy and maximize the value of the lithium-rich brine with cutting-edge extraction technology.

About Adionics

ADIONICS is a private French company bringing a technology breakthrough in selective lithium salt extraction from continental, geothermal or produced water brines. Its brine mining solution is based upon unique cation selectivity, using “lock and key model,” using a highly customized proprietary salt extracting liquid formulation named Flionex®. Using Flionex within a now patented thermal swing liquid-liquid deionization process, you get a remarkable and unique solution to selectively extract Lithium salts from brines with remarkably high lithium recovery using a reagent free sustainable technology with very limited water usage.

Contact: François-Michel Colomar, Sales Director, francois-michel.colomar@adionics.com, +33 (0) 6 30 41 24 05 , www.adionics.com