Applied R&D to support technology

ADIONICS has a strong foundation built upon extensive research and development expertise, facilitated by cutting-edge laboratory and advanced analytical capabilities. Through our dedication to R&D, we have achieved numerous milestones and breakthroughs.

Whether ADIONICS is Flionex®, improving existing processes, or addressing emerging market demands like battery recycling, we are able to provide any high quality solution.

Our R&D service is a hub of creativity and exploration, where our team of 25 skilled scientists, engineers and researchers collaborate to exceed the boundaries of knowledge and develop groundbreaking solutions to extract sustainable lithium.

CHEMISTRY DEPARTMENT

Innovation is the leading word of this dynamic team. Researchers as Technicians, Engineers, PhDs work daily on new solutions, methodologies, and ideas to customize Flionex® according to the type of brines or process effluents (recycling, hard rock…) to extract.

They create specific molecules, invent new formulations and work continuously on the optimisation and development of Flionex®:

- Organic synthesis expertise

- Inorganic and materials chemistry expertise

- Formulation (combining new powerful and selective molecules)

- Computing modelization skills

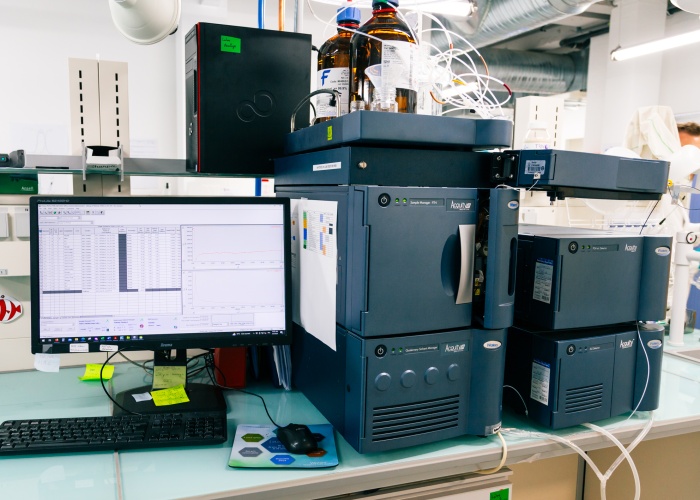

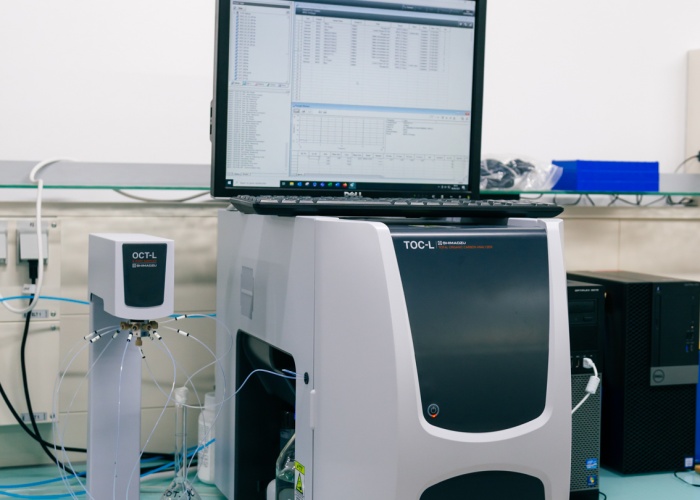

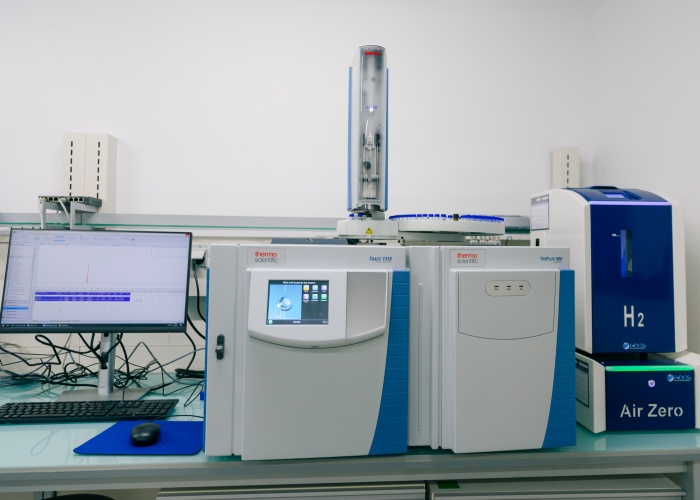

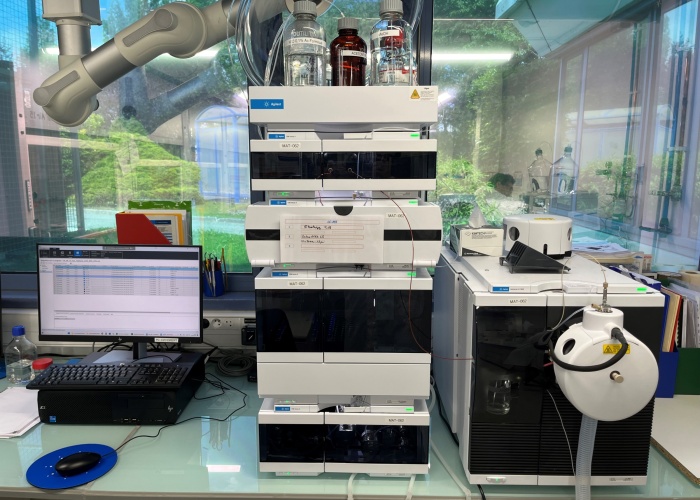

ANALYSIS DEPARTMENT

The analytical chemistry department emphasizes continuous improvement and responds to clients’ needs.

Technicians and researchers regularly review and refine analysis methodologies, tools and processes to enhance accuracy and efficiency of ADIONICS’ cutting-edge technology.

- Development and validation of chemical analysis methods

- Mineral and organic chemical analysis (raw materials, formulation, and finished products)

- Various and varied analytical techniques: Liquid, Ionic and Gas chromatography – ICP – Karl Fischer titration – Total Organic Carbon-meter – Viscometer – Densimeter – R&D programs, etc

- Embracing 24/7 operation capabilities to meet ADIONICS’ specifications.

PROCESS DEPARTMENT

The process department is involved in designing the overall process for the plant and in the selection of the optimal technologies for our disruptive Process. We are focused on optimizing extraction processes to maximize lithium recovery while minimizing energy consumption, water usage, and environmental impact.

This involves conducting experiments, simulations, and pilot-scale trials to evaluate different process parameters and identify the most efficient operating conditions.

- Predictive process performances

- Validation of isotherms and performance predictions

- Demonstration of post treatment efficiency

Adionics guides complete solutions from design to commissioning.